The Complete Detailing & Protection Guide

How is Detailing a vehicle different from Washing? And why is Paint Protection important?

Ceramic Coating, PPF, Graphene Coating etc.

All you need to know!

Regular Vehicle Washing: A routine wash gets rid of dust and dirt on the outside of your vehicle, and if you clean the interior you may get surface dirt off the carpet with a wet cloth or vacuum, but thats about it.

Driving down to the nearest wash station costs you time, most likely a diluted foam wash and a bit more intensive vacuuming. Common applicators and dirty rags spread contamination from one vehicle to another and you are still unsatisfied.

Eventually you end up with a vehicle that looks dull and faded, a rough paint surface, interiors that just won’t clean up anymore and an engine bay that looks like hell. Thats where Detailing comes in.

Vehicle Detailing: Getting your car or bike detailed involves a top-to-bottom intensive deep cleaning and reconditioning of your vehicle using specialised machines, instruments, products and tools.

Detailing removes impurities, surface scratches and swirl marks from paint, reconditions the interiors and tackles the engine bay of the car, removing all dirt, dust, road tar, grime and paint contamination along the way.

The aim of this entire process is to restore the vehicle to as near factory condition and sometimes even better than when it left the dealer. (Yes! Sometimes we even detail brand new cars prior a Ceramic coating or PPF)

A full detail is a time intensive process and can take anywhere between 7 to 9 hours per vehicle. Needless to say, the end results will absolutely blow your mind!

- EXTERIOR DETAILING STEPS-

Compressed Air Cleaning - Using a blast of compressed air we get rid of all dirt, dust and other contaminants on the exterior surface to prep the vehicle for a foam wash.

Mineral Deposits/ Hard Water Spots Removal - Using an effective water-spot remover to tackle water spots, stubborn stains and Logo's which have water-spot marks. Using a fine brush this is a slow but effective process. We wipe each section immediately as this is a powerful cleaner and should not be left on the paint for too long.

Chrome & Metal Polish - We use a specialised metal polish and stain remover for the exterior chrome strips and Logo's and other metal surfaces to remove all ingrained stains and restore gloss and shine. Chrome attains a mirror finish and looks its best.This cream is powerful and should be wiped off immediately after its applied.

Clay Bar & Iron-X Decontamination - One of the most time consuming steps of the detail process. We clay the vehicle using a good quality, clean clay bar. If required an Iron-X solution is sprayed onto your vehicle to remove Iron impurities which clay cannot get to. This step removes nearly all contamination from your paints surface. We also clay the glass, headlamps and tail lamps for surface contamination.

Foam Wash - Thick pH neutral auto grade foam is sprayed over the entire vehicle that clings to the surface and removes dirt and grime effectively. Finally a sponge is used to agitate the foam and is pressure washed off.

Suspension/ Wheels – We use a combination of high pressure water, specialised wheel cleaner spray and lug nut brushes for maximum cleaning. We also clean the suspension struts, the wheel arches, wheel wells and the accessible underbody is spray cleaned. We use a matt black UV dressing for the wheels and tires which helps keep them dust-free and dark black for longer.

Air Drying - We dry your vehicle using a blower. Anytime you can avoid touching the paint you reduce the chances of adding scratches and swirls. After the blow dry we use a damp microfibre towel to catch any water streaks left over.

Headlights/ Tail Lamps - A soft microfibre applicator and premium UV protectant coating is applied onto the headlamps and tail lights to make them shiny and slick, offer better clarity and keep them clean longer against contamination and environmental damage.

Paint Correction - This is the part where the orbital buffer comes out. Depending on the paint type, condition and how much work it needs, we choose our compounds and buffing pads accordingly. We carry a varied selection of polishes, compounds, foam and wool pads to tackle most lacklustre painted surfaces.

Paint Sealant - Once the paint correction is done, it’s time to protect and seal the paint. We use a polymer paint sealant. Hand applied and hand buffed for a deep intensive shine and gloss. It’s a good idea to let the sealant cure for 4 hours We've found paint sealant is best because it lasts much longer than a traditional wax and delivers a far superior shine.

- INTERIOR DETAILING STEPS -

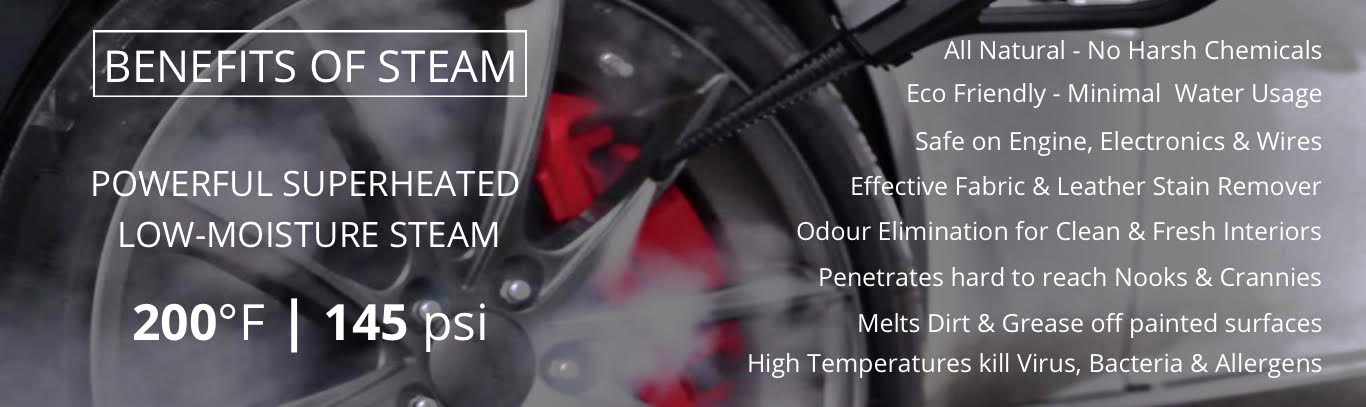

Cabin/ Interior Trim - Using a combination of high temperature steam, scrubbing, and specialised APC cleaners, we touch on every bit of interior plastic trim and door pads and panels for a thorough stain removal and deep cleaning.

Carpets/ Headliner - Carpets are deep cleaned with a heavy duty vacuum and carpet brush. Shampoo cleaned for stain removal and wet extraction is done for a super clean and fresh smelling carpet. The headliner is dry cleaned and brushed as its adhesives don’t take kindly to aggressive cleaning and steaming.

Doors/ Armrests/ Wheel/ Gear Lever - Sometimes the dirtiest areas due to being common touch points within the cabin. Steam cleaning gets rids of stubborn stains and embedded dirt and then APC cleaners and soft scrubbers are used to restore and clean the areas and parts to a detailed clean condition.

Leather Seats & Trim – Leather trim/ seats require special care during the interior detailing stage. We use a high-quality leather cleaner and conditioner cream to protect your leather seats, surfaces and leather trim. Once done, the leather achieves a soft supple feel with a distinct leather fragrance and feels smooth to touch.

Fabric Seats - Using an APC cleaner and shampoo the seats are cleaned and scrubbed thoroughly. Wet extraction vacuuming is done to remove excess moisture and then a blower attains near 95% dryness on completion. Fabric seats need at least 4 to 5 hrs of air drying time to dry completely.

A/C Vents/ Intakes - Steam sanitisation of the entire A/C system is done. Both for intake and discharge vents to ensure maximum steam penetration and cleaning of germs and bacteria embedded within the system.

UV Protectant Polish - The entire cabin, plastic trim and untreated areas are coated using a soft microfibre applicator and premium UV protectant for ultimate long term protection against fading and whitening.

- ENGINE BAY DETAILING -

Engine Bay - Detailing a vehicle while leaving the engine bay untouched is just not how it’s a proper detail is done. One of the most intensive and required jobs, detailing the engine bay is as important as the rest of the vehicle. A clean engine bay speaks volumes about the vehicles upkeep and it is easier to spot leaks, spills and any breakdown signs much before it actually happens.

We use a combination of dry-steam, powerful engine degreaser and our brushes and crevice detailers to tackle even the most dirtiest engine bay. Once done, we blow dry and dress the engine bay with our UV protectant polish which keeps the vital components dust-free and clean for longer.

Detailing a vehicle is not an easy one-size-fits-all formula which applies everywhere. Each unique vehicle presents its own set of challenges and puts out different requirements with its age, colour, maintenance history and usage. And there’s only so much you the owner can achieve with DIY products, equipment and time.

Thats where we the professional team at DirtyClean Auto Detailing come in. We bring detailing services right to your door, saving you time and effort with the stress free convenience of getting your vehicle detailed wherever you are!

Heck we even carry our own power and water so you don’t need to be bothered with buckets and wires and what-not!

With results that speak for themselves and our absolute Guarantee that you will love how we transform your vehicle after we’re done, give us a call and experience first-hand what a proper detail feels like.

***********************************************************

- CERAMIC COATING & FAQ's -

You want to keep your vehicle safe from harm and protected from anything the elements or the road can throw its way. This is where coatings come into play – these durable, effective solutions create a strong and lasting barrier between your vehicle's surfaces and the outside world.

But there is more than one choice available to you when you search for a coating. Which one is more effective?

The market is continuously evolving with newer and varied methods. At one point carnauba wax was the go-to product for protection and shine. Then it was polymer sealants and teflon coating, and today, the latest advancement is ceramic coating.

What is a Ceramic Coating?

Ceramic coating is typically composed of silicon dioxide (silica, Si02), which is sourced from natural materials such as quartz and sand. Some types and brands also use titanium dioxide (titania, Ti02) or Graphene infused Ceramic. There are several grades of ceramic coating on the market today. But most Ceramic coatings follow the same molecular chemical structure and installation methods.

How does a Ceramic coating work?

When applied to a vehicles paint or any non porous surface, it creates a strong chemical bond with the applied surface on a nano molecular level with excellent hydrophobic properties.

It does this through nanotechnology that allows the product to bond to your paint, wheels, glass, and trim at a molecular level. This fills in microscopic pits and grooves in your paint leaving a hydrophobic surface that is so smooth that it actually feels “slick” to the touch.

In simpler terms, Ceramic coating is a long-term exterior automotive paint treatment and protectant that is applied in a liquid form and cures to form a hard shell on top of the factory paint. Essentially, it's a hard wearing sacrificial layer over your factory finish that bears the brunt of the contamination & environmental damage while offering long term paint protection.

It is designed to protect from UV light, chemicals, tree sap, brake dust, and other external contaminants which harm the paint finish.

What are the benefits of a Ceramic coating?

Some of the qualities that result due to applying a ceramic coating include:

Hydrophobic Properties: This is the ability to repel water, liquids, mud, dirt, and other light debris. The super slick coated surface doesn’t allow contaminants or liquids to sit on the surface easily and repels free flowing liquids and loose dust from the vehicles surface. Water simply beads off.

Protection from UV Light: Long term UV exposure leads to paint fading, stimulating oxidation, which ultimately results in corrosion and the development of rust. Ceramic coated paint blocks UV from causing this type of damage.

Protection Against Chemicals: Chemicals such as road salt, tar splatter and acids found in animal waste (like bird droppings and bug splatters) can cause damage to your paint. The ceramic coating’s ultra-slick surface blocks these contaminants from penetrating to the original factory finish and helps protect the gloss and shine for longer.

Improved Gloss and Reflections: When ceramic coating cures, it is closer in structure to a layer of liquid glass. Once applied, this amplifies the original shine of the paint, makes matte finishes or plastic trim appear deep and rich, and allows alloy wheels to pop. The coated surface literally behaves like a mirror. This is one of the most desirable and easily visible features of a Ceramic coating that owners simply love.

Simplifies Cleaning: Arguably the best feature of a ceramic coating is the non-stick properties, making it harder for dirt to stick and easier to remove. This acts as a self-cleaning property, as wind produced while driving simply blows away contaminants – keeping the vehicle cleaner for longer periods. At times, just a light water spray is more than enough to restore the vehicle back to a clean look. Minimal effort and water usage keeps maintenance to a minimum.

What Does a Ceramic coating NOT Do?

Scratch Proof your Vehicle: Ceramic coatings DO NOT make a vehicle Scratch proof. While most professional grade coatings can resist scratching to a certain degree – they are not 100% scratch proof. They can protect the factory paint surface from light to medium scratches and damage, but the coating itself may likely get scratched.

NO need to Wash Your vehicle: While a Ceramic coated vehicle is extremely slippery and definitely harder for dirt to stick to, eventually every vehicle will need to get washed. While maintaining the exterior on a Ceramic coated vehicle will definitely be easier requiring less effort and water, it still requires routine washing and cleaning.

Fire proof your Vehicle: There are some claims that a Ceramic coated vehicle is Fire proof. Absolutely NOT! You’ll see some videos where they pour some flammable fluid and light it, put out the fire in a few seconds, then simply wipe off the residue with a microfibre towel. This is more of a gimmick and simply does nothing to make your vehicle fire-proof.

Self-Healing properties: Ceramic coating forms a solid clear layer on top of your vehicles factory finish. Unlike PPF (Paint protection film) when it’s scratched, nano-technology infused in a high-quality PPF will literally repair the scratch in a matter of minutes. But this isn’t possible with a solid ceramic coating. It is a solid clear coat and offers no flexibility and stretchability to self-heal.

When should I use a Ceramic Coating?

Ceramic coating should only be applied once your vehicle has been thoroughly detailed and paint corrected and the paint has been restored to as near factory condition. Or if your vehicle is brand new and you are looking to preserve that factory finish look for the long term before environmental damage and contaminants take their toll. Irrespective of the condition, any vehicle with paint in decent condition can be Ceramic coated after proper prepping and thorough surface treatment.

What are the different Coatings available?

Teflon-Based Coating - Made from Teflon and Silicones that have similar structures as Ceramic. They are made to replicate attributes – like hydrophobic properties, a slippery look, and enhanced gloss. However, they have a short lifespan and ineffective to protect against swirl marks and more about enhancing looks than offering any real long term protection.

Paint Sealant - A sealant is a paint protective product that is made up of liquid polymers. If they contain wax, they are considered hybrids. Sealants come in several different types and are the step between natural wax and completely synthetic protective products like Ceramic coating.

Ceramic Boost Spray - These are closer to professional-grade coatings, but diluted. They contain about 20% strength of a standard Ceramic coating liquid. Easy to apply, just spray on the vehicle’s surface, buff off, and let it air cure for about 4 hours. They provide similar features to a Ceramic coating for about 3 months but are ineffective as a long-term solution.

What is meant by 9H or 10H hardness?

Ceramic coatings are highly-concentrated formulas that provide superior protection on paint, chrome, carbon fibre, and even vinyl or paint protection film (PPF). To measure how well a coating performs after curing a series of test readings are measured against a scale and the hardness (H) level is displayed as a number.

The 9H is the highest on the pencil scale of hardness. It is basically as hard as a solid quartz crystal. 10H coatings use the Mohs scale and is a different grading method from the pencil scale. 10 on a Mohs scale is equivalent to the hardness of a diamond. The ‘H’ common in both scales can be confusing at times.

Unfortunately manufacturers exaggerate their claims to offer a perceived hardness level of the coating and use different scale to offer a perceived higher level of durability and longevity.

Needless to say most Pro-grade Ceramic coatings are extremely durable and nearly all genuine Ceramic coatings achieve a 9H hardness. It is the surface longevity and durability that differs from one to the other.

How do I choose? Are all Ceramic coatings the same?

There are different grades of Ceramic coating available right from the DIY products to Pro-grade Coatings installed by trained technicians and offered with a warranty.

DIY Ceramic coating: With a little bit of technical knowledge and the right tools, the average vehicle owner can apply a generic Ceramic coating. Available off-the-shelf and at relatively cheaper rates, DIY coatings are generally not a strong as the professional-grade coatings and is formulated to allow the average enthusiast to apply with a relative lack of experience. These products range from an SiO2 percentage of 50% to about 75%. Although not all products are suspect, knock-off’s are rampant in the market and marketed and sold as Ceramic.

The quality and results of these products are hard to predict, and usually contain no warranties. Again, without proper paint correction and surface prep. the results vary and sometimes could end up as an imperfect job which will take serious time, money and effort to correct.

Pro-grade Ceramic coating: These manufacturer backed coatings are precision formulated and highly concentrated with SiO2 concentrations higher than 90% guaranteeing unmatched long term protection and durability.

Applications are done by trained technicians in a dust free and controlled environment to ensure optimal results with proper detailed paint correction and surface preparation. A professional Ceramic coating application is backed by a manufacturer warranty and generally offers maintenance services for the warranty duration to ensure the coating performs as it should. Ceramic booster applications are generally included in the cost and in the long run work out to be cost effective and a better return on your investment.

Overall, a Pro-grade ceramic coat simply holds up for extended periods. It acts as a stronger sealant, reduces minor scratches, and has superior wear resistance. Backed by a manufacturer warranty and continuous maintenance services to ensure the coating performs as it should.

Is a Ceramic coating worth it?

Yes absolutely! A ceramic coating is a great way to protect your daily driver or valuable vehicle.

Ceramic coatings are absolutely amazing products, especially when they are installed properly, maintained regularly, and contain the right balance of ingredients.

A well maintained nano ceramic coating has the ability to provide protection and shine for years on end, especially if routinely rejuvenated with an SiO2 ceramic booster.

You can expect to receive a substantial 2–5 years of protection although vehicle care procedures and routine booster sprays must be followed.

If you’re thinking about investing in a ceramic coating for your vehicle for maximum protection, enhanced shine and longevity – do your research. Choose a Coating brand that offers a warranty, manufactured by an Internationally recognised detailing company and one that fits your needs, budget, and provides you with the best return on your investment.